Product Description

|

Spec |

|

|

Polymer |

NR/SBR |

|

Density |

1.246 |

|

Hardness (Shore A) |

60±5 |

|

Tensile strength (MPA) |

14(≥14) |

|

Elongation (%) |

640(≥400) |

|

Wear (mm3) |

178(≤200) |

|

Tearing strength (N/mm) |

51 |

|

Temp (ºC) |

-40-110 |

Note: Can be produce according the client’s requirement

|

Product No. |

Thickness |

Width |

Length |

|

6832501 |

12/15/20mm |

100-500mm |

1200mm |

|

6832450 |

12/15/20mm |

100-500mm |

1450mm |

|

6832451 |

12/15/20mm |

100-500mm |

1650mm |

|

6832783 |

12/15/20mm |

100-500mm |

1850mm |

|

6832258 |

12/15/20mm |

100-500mm |

2100mm |

|

6832452 |

12/15/20mm |

100-500mm |

10m |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Natural Rubber |

|---|---|

| Usage: | Industrial |

| Feature: | Wear-resistant, Heat-resistant, Corrosion-resistant, Cold-resistant |

| Raw Materials: | Natural Rubber, Pad |

| Medium: | Pure Gum Rubber Sheet and Fabric |

| Performance: | Insulating Rubber Slab |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

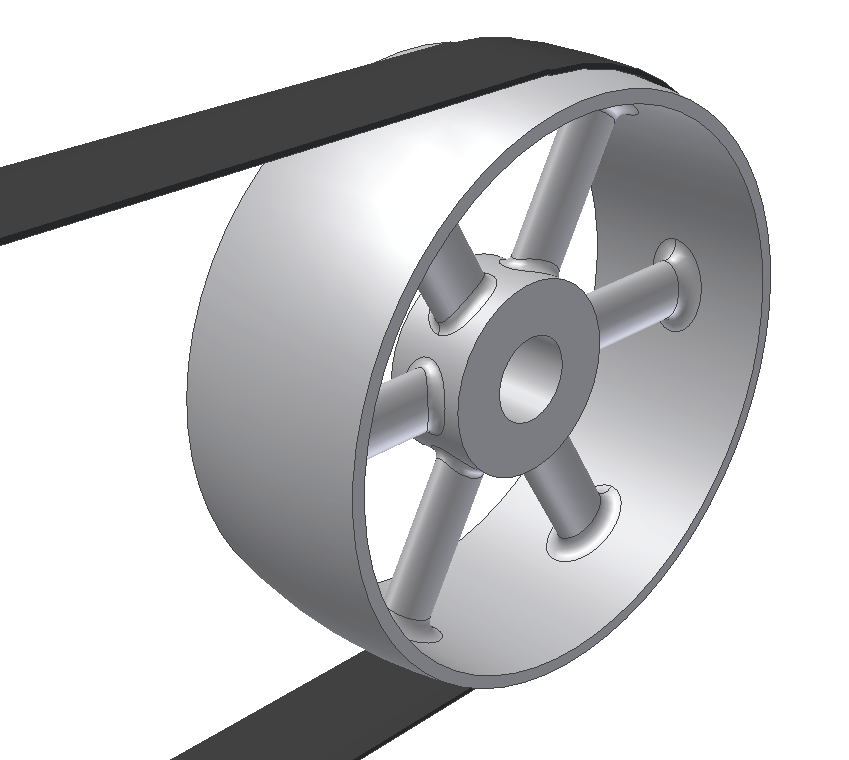

Can flat belt pulleys be used in both simple and complex mechanical systems?

Flat belt pulleys are versatile components that can be used in both simple and complex mechanical systems. Here’s a detailed explanation:

1. Simple Mechanical Systems:

In simple mechanical systems, flat belt pulleys are often employed for basic power transmission tasks. These systems typically involve a single pulley or a few pulleys connected by a flat belt. Simple systems may include applications such as:

- Driving conveyor belts in industrial settings

- Powering agricultural machinery

- Operating fans and blowers

- Driving pumps and compressors

- Transferring power in basic mechanical assemblies

Flat belt pulleys are well-suited for these applications due to their simplicity, ease of installation, and cost-effectiveness. They provide reliable power transmission and can handle moderate loads and speeds.

2. Complex Mechanical Systems:

In complex mechanical systems, flat belt pulleys can be integrated into more intricate setups involving multiple pulleys, shafts, and various components. These systems may have additional features such as:

- Multiple belts and pulley sets for increased power transmission capacity

- Tensioning mechanisms for maintaining proper belt tension

- Idler pulleys for belt routing and improved belt contact

- Clutches or variable speed drives for adjustable power transmission

- Overload protection mechanisms

Complex mechanical systems that utilize flat belt pulleys can be found in a wide range of industries and applications. Some examples include:

- Manufacturing and production lines

- Automotive assembly plants

- Printing and packaging machinery

- Textile manufacturing equipment

- Material handling systems

- Industrial automation systems

Flat belt pulleys in complex systems provide precise and efficient power transmission, allowing for the synchronization of multiple components and the control of various operating parameters.

Whether in simple or complex mechanical systems, flat belt pulleys offer advantages such as smooth operation, high efficiency, and the ability to transmit power over long distances. Their versatility makes them suitable for a wide range of applications, from basic setups to advanced and sophisticated machinery.

How do flat belt pulleys handle different belt sizes and materials?

Flat belt pulleys are designed to accommodate different belt sizes and materials to ensure efficient power transmission. Here’s a detailed explanation:

1. Belt Sizes:

Flat belt pulleys are available in various sizes to match different belt widths and thicknesses. The width of the pulley’s groove is designed to provide proper contact and grip with the belt. Pulleys with wider grooves are used for wider belts, while narrower grooves are used for narrower belts. The pulley’s diameter may also vary depending on the specific application and power requirements.

2. Belt Materials:

Flat belt pulleys can handle a wide range of belt materials, including:

- Rubber: Rubber belts are commonly used due to their flexibility, high friction coefficient, and resistance to wear. They provide good grip and are suitable for most general-purpose applications.

- Polyurethane: Polyurethane belts offer high resistance to abrasion, oil, and chemicals. They are often used in applications that require superior performance and durability.

- Leather: Leather belts are known for their high strength and flexibility. They are used in applications where a certain level of slip is required or to transmit power in antique or vintage machinery.

- Nylon: Nylon belts are lightweight, have high tensile strength, and offer good resistance to wear and moisture. They are commonly used in applications that require low noise and high load capacity.

3. Belt Tensioning:

Flat belt pulleys should be designed with a tensioning mechanism to accommodate different belt sizes and maintain proper tension. This mechanism, such as an idler pulley or tensioning screw, allows for easy adjustment of the belt tension to ensure optimal power transmission and prevent slippage.

4. Belt Tracking:

To handle different belt sizes and materials, flat belt pulleys should be designed to provide proper belt tracking. This ensures that the belt stays within the pulley’s groove and maintains alignment during operation. Proper flanges or guides are often incorporated into the pulley design to prevent the belt from slipping off or wandering.

5. Material Compatibility:

The materials used in flat belt pulleys should be selected to be compatible with the specific belt materials. For example, if using a rubber belt, the pulley material should not cause excessive wear or damage to the belt’s surface. Compatibility between the pulley and the belt material helps ensure optimal performance and longevity.

By considering these factors, flat belt pulleys can effectively handle different belt sizes and materials, providing reliable power transmission in a wide range of applications.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2024-04-04