Product Description

Chain Pulley Gearbox Wood Garden Wall Crankshaft Plant Km Series Belt Flat Taper Lock Cable Machine Tensioner PRO Fitness Attachment System Arm Tricep Suppliers

Application of Chain Pulley

Chain pulleys are a type of pulley that uses a chain instead of a rope or cable. They are typically used in applications where a high lifting capacity is required, such as in construction and manufacturing.

Chain pulleys work by using the chain to wrap around a wheel or drum. When you pull on the chain, it turns the wheel or drum, which in turn lifts the load. Chain pulleys can be used to lift heavy loads with less effort than if you were to lift them manually.

Chain pulleys are available in a variety of sizes and capacities. The size of the pulley will depend on the weight of the load that you need to lift. The capacity of the pulley will depend on the amount of force that you can apply to the chain.

Chain pulleys are a versatile tool that can be used in a variety of applications. They are typically used in construction and manufacturing, but they can also be used in other applications, such as:

- Agriculture

- Mining

- Logistics

- Warehousing

- Marine

Chain pulleys are a safe and reliable way to lift heavy loads. They are easy to use and maintain, and they can be used in a variety of applications.

Here are some of the advantages of using a chain pulley:

- High lifting capacity. Chain pulleys can lift heavy loads with less effort than if you were to lift them manually.

- Durability. Chain pulleys are made from high-quality materials that can withstand heavy use.

- Versatility. Chain pulleys can be used in a variety of applications.

- Ease of use. Chain pulleys are easy to use and maintain.

If you are looking for a way to lift heavy loads with less effort, then a chain pulley is a great option.

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can flat belt pulleys be used in both simple and complex mechanical systems?

Flat belt pulleys are versatile components that can be used in both simple and complex mechanical systems. Here’s a detailed explanation:

1. Simple Mechanical Systems:

In simple mechanical systems, flat belt pulleys are often employed for basic power transmission tasks. These systems typically involve a single pulley or a few pulleys connected by a flat belt. Simple systems may include applications such as:

- Driving conveyor belts in industrial settings

- Powering agricultural machinery

- Operating fans and blowers

- Driving pumps and compressors

- Transferring power in basic mechanical assemblies

Flat belt pulleys are well-suited for these applications due to their simplicity, ease of installation, and cost-effectiveness. They provide reliable power transmission and can handle moderate loads and speeds.

2. Complex Mechanical Systems:

In complex mechanical systems, flat belt pulleys can be integrated into more intricate setups involving multiple pulleys, shafts, and various components. These systems may have additional features such as:

- Multiple belts and pulley sets for increased power transmission capacity

- Tensioning mechanisms for maintaining proper belt tension

- Idler pulleys for belt routing and improved belt contact

- Clutches or variable speed drives for adjustable power transmission

- Overload protection mechanisms

Complex mechanical systems that utilize flat belt pulleys can be found in a wide range of industries and applications. Some examples include:

- Manufacturing and production lines

- Automotive assembly plants

- Printing and packaging machinery

- Textile manufacturing equipment

- Material handling systems

- Industrial automation systems

Flat belt pulleys in complex systems provide precise and efficient power transmission, allowing for the synchronization of multiple components and the control of various operating parameters.

Whether in simple or complex mechanical systems, flat belt pulleys offer advantages such as smooth operation, high efficiency, and the ability to transmit power over long distances. Their versatility makes them suitable for a wide range of applications, from basic setups to advanced and sophisticated machinery.

What safety considerations should be kept in mind when working with flat belt pulleys?

Working with flat belt pulleys involves certain safety considerations to prevent accidents and ensure safe operation. Here’s a detailed explanation:

1. Machine Guarding:

It is important to ensure that flat belt pulleys are properly guarded to prevent accidental contact with rotating parts. Guards should be in place to cover the pulley and belt, minimizing the risk of entanglement or entrapment of clothing, body parts, or tools.

2. Lockout/Tagout Procedures:

Prior to performing any maintenance or servicing tasks on machinery equipped with flat belt pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, locking out the equipment, and clearly tagging it to indicate that maintenance work is in progress. This helps to prevent inadvertent startup of the machinery, which could cause serious injuries.

3. Personal Protective Equipment (PPE):

When working with flat belt pulleys, appropriate Personal Protective Equipment (PPE) should be worn. This may include safety glasses or goggles to protect the eyes from debris or flying particles, gloves to protect hands from sharp edges or pinch points, and hearing protection if the machinery generates excessive noise.

4. Training and Education:

Operators and maintenance personnel should receive proper training and education on the safe operation and maintenance of machinery with flat belt pulleys. They should be familiar with the potential hazards associated with these systems and understand the correct procedures for installation, tensioning, and adjustment of the belts.

5. Regular Inspections and Maintenance:

Flat belt pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent further damage or potential accidents. Routine maintenance, including belt replacement, lubrication, and tension adjustments, should be performed according to the manufacturer’s recommendations.

6. Handling Heavy Loads:

When working with machinery that utilizes flat belt pulleys for heavy load transmission, proper lifting techniques should be employed to prevent strains or injuries. Mechanical lifting aids or equipment should be used as necessary to safely handle heavy loads.

7. Risk Assessment:

A thorough risk assessment should be conducted to identify and mitigate potential hazards associated with flat belt pulleys. This includes evaluating the layout of the machinery, the positioning of pulleys and belts, and any other factors that may pose a risk to the safety of operators or maintenance personnel.

By adhering to these safety considerations, the risk of accidents or injuries when working with flat belt pulleys can be significantly reduced. It is essential to follow industry best practices, manufacturer’s guidelines, and applicable safety regulations to ensure the safe operation of machinery equipped with flat belt pulleys.

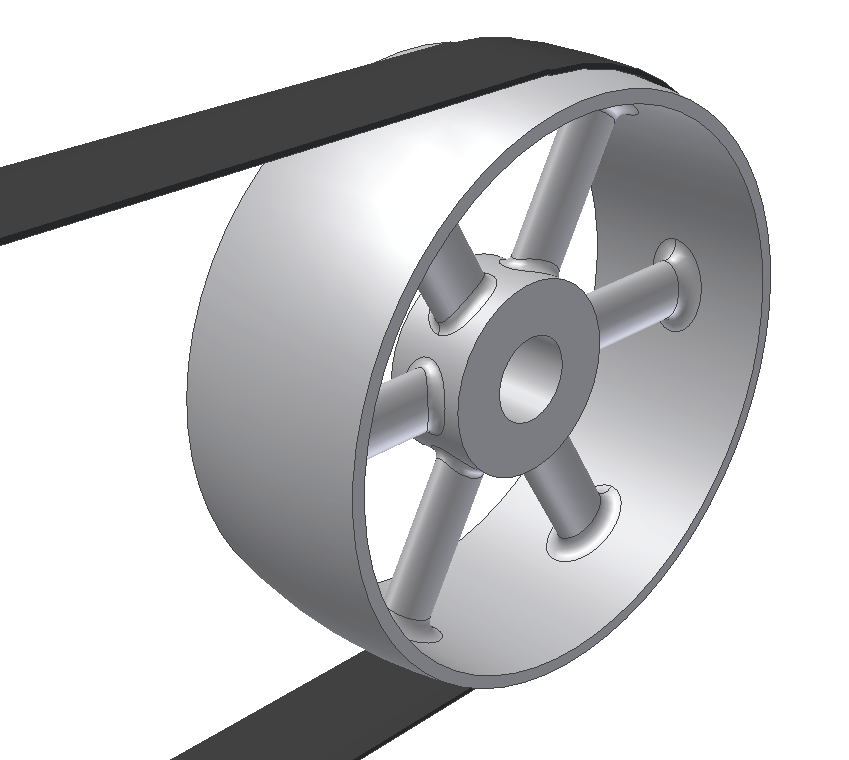

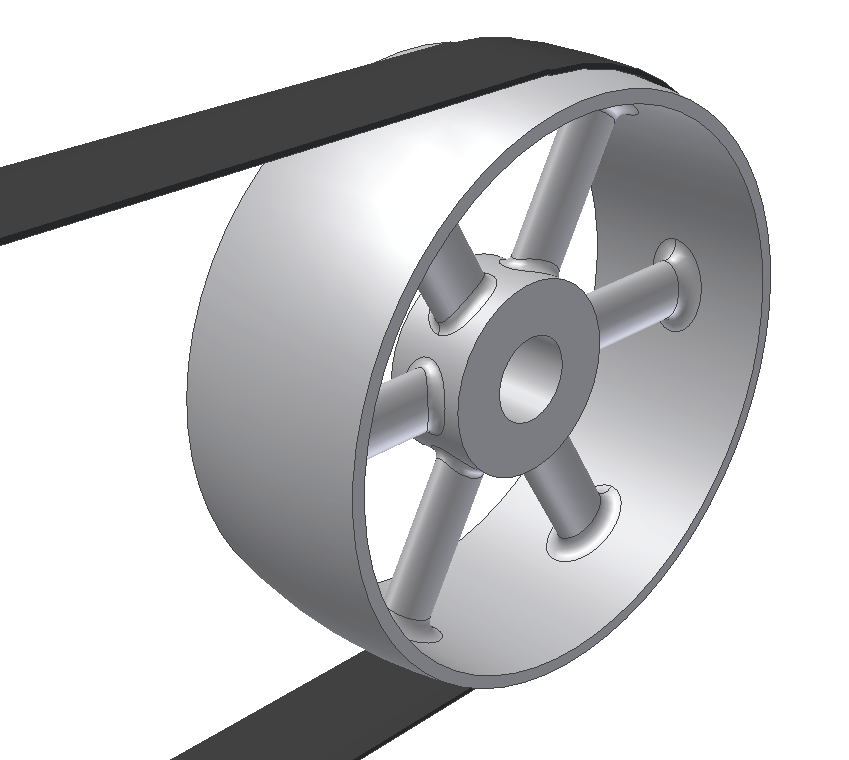

What is a flat belt pulley, and how does it function in machinery?

A flat belt pulley is a type of pulley used in machinery that utilizes a flat belt for power transmission. Here’s a detailed explanation:

1. Design and Construction:

A flat belt pulley consists of a cylindrical or disk-shaped body with a flat or slightly concave surface. It is typically made of durable materials such as cast iron, steel, or aluminum. The pulley may have one or more grooves or channels on its surface to accommodate the flat belt, ensuring proper engagement and power transfer.

2. Power Transmission:

The primary function of a flat belt pulley is to transmit power from a driving source, such as an engine or motor, to a driven component in machinery. The flat belt connects the driving pulley (also known as the driver) to the driven pulley (also known as the driven). As the driving pulley rotates, it imparts rotational motion to the flat belt, which in turn transfers the power to the driven pulley. This enables the driven component to perform its intended function.

3. Belt Grip and Traction:

A flat belt pulley provides grip and traction on the flat belt, ensuring efficient power transfer and minimizing slippage. The design of the pulley surface, including any grooves or channels, helps maintain proper belt engagement and prevents the belt from slipping or coming off the pulley during operation. The pulley’s material and surface finish are chosen to optimize friction and traction between the pulley and the belt.

4. Speed and Torque Conversion:

By varying the size of the flat belt pulleys in a machinery system, the rotational speed and torque can be converted according to the desired requirements. The ratio of the pulley diameters determines the speed ratio between the driving and driven components. For example, a larger pulley on the driving side and a smaller pulley on the driven side will result in increased speed at the driven component but reduced torque. This allows for the customization and adaptation of machinery to different operational needs.

5. Tension and Alignment:

A flat belt pulley aids in maintaining proper tension and alignment of the flat belt. Tensioning mechanisms, such as adjustable pulley positions or tensioners, are utilized to ensure optimal tension in the belt. Proper tension prevents slippage and ensures the belt remains tightly engaged with the pulleys. Additionally, flat belt pulleys may incorporate features like crowned surfaces or tracking guides to aid in belt alignment, reducing the risk of misalignment and optimizing power transmission.

6. Maintenance and Replacement:

Regular maintenance and inspection of flat belt pulleys are essential for their proper functioning. It is important to check for wear, damage, or misalignment of the pulley and the flat belt. Any worn or damaged pulleys should be replaced promptly to prevent performance issues and potential failures in the machinery.

In summary, a flat belt pulley is a key component in machinery for power transmission using flat belts. It provides grip and traction, facilitates speed and torque conversion, aids in tension and alignment, and requires regular maintenance to ensure optimal performance.

editor by CX

2023-09-30